The era of green hydrogen leads to rethink co-location – PV Magazine International

[ad_1]

Wind turbines and solar PV can work together in symbiosis, and in deserts bordering the seas in particular, this relationship is particularly “anti-correlated”, that is, the sun shines during the day and the wind blows. the night.

This ensures, for example, a plant to produce green hydrogen, a renewable energy source almost 24/7 in a newly popular location. It seems then that the world’s wastelands no longer exist, as they are now the most desirable places on the planet for our energy future and the reduction of emissions.

Over the past 18 months, hybrid power plants have become more common for their ability to complete the lifeline of a generator – their connection to the grid. That’s why Swedish state-owned energy company Vattenfall invested € 35 million in 2019 to add solar and energy storage to its Haringvliet onshore wind project in South Holland. However, when it comes to the production of green hydrogen, connection to the grid is not even always necessary. The most important is the co-location of solar and wind power.

So why is the co-location of solar and wind power important for the production of green hydrogen?

Benefits of co-location

BP and its Lightsource BP solar joint venture are concluding a feasibility study on the prospect of a co-located 1.5 GW green hydrogen wind and solar power plant in Western Australia, with the ambition to export green hydrogen in the form ammonia to Asia.

Scott Orchard, a project developer at bp Australia, told pv magazine that “Co-locating renewables with a hydrogen / ammonia plant has the benefit of reducing the necessary transport infrastructure. [power lines]. If configured so that the plant is connected only to renewable energies on site, infrastructure costs are better controlled compared to the project, with potential savings on network costs. “

Ad van Wijk, professor of future energy systems at TU Delft, agrees with Orchard, noting that in the case of green hydrogen, “a connection to the grid is not necessary. What you want is to produce in places with very low cost of electricity, with solar and wind, and then you ship hydrogen … the idea is that the combination of solar and wind can sometimes have a better capacity factor. Wijk points to Neom, a green city under construction in Saudi Arabia. “There is a very good wind and a very good solar… But what is the wind there? It is a sea wind produced when a hot desert meets a cold sea. “

This almost perfect anti-correlation makes these locations ideal for clean energy production. Warm air rises above the landmass throughout the day, causing a cold wind from the sea to replace it. That is, the wind rises when the sun goes down.

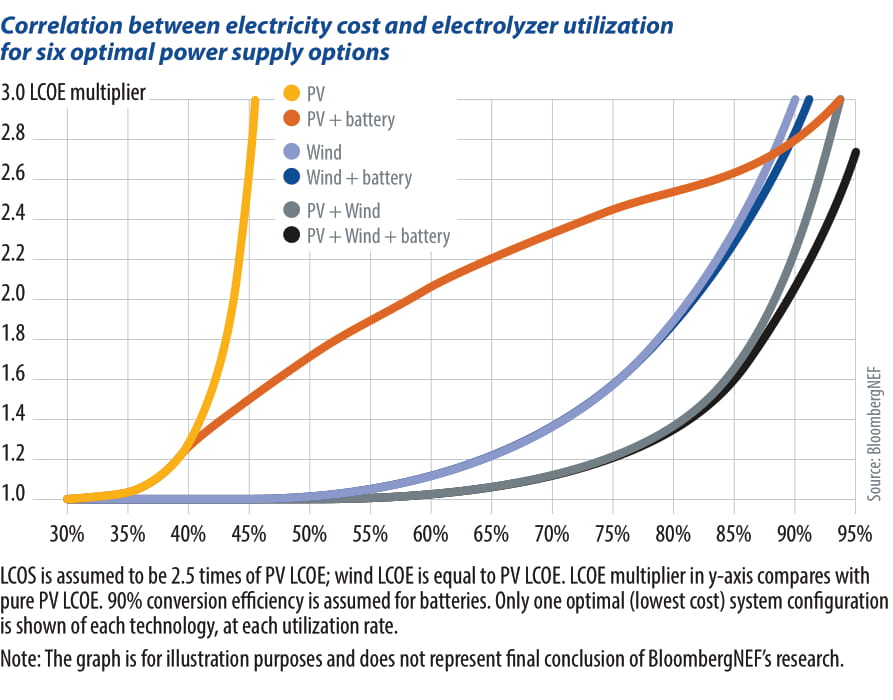

Xiaoting Wang, BloombergNEF’s lead researcher on green hydrogen production, pointed out that “coupling” was a key factor in the leveling cost of the hydrogen equation.

Wang recently hosted the hydrogen panel with the president of Air Products as part of the BNEF Energy Summit, and told PV magazine that Air Products chose Neom because of the cheap electricity provided by its energies. large-scale co-located renewables. And that without Air Products’ specific need for a nitrogen plant, the entire project would not require battery energy storage at this stage, co-location would be sufficient. While the economics of Neom’s takeover bids are not being disclosed, it can be assumed that large-scale green hydrogen projects looking to start before 2030 may not necessarily require battery energy storage. and that savings could prove crucial for the rapid development of the scale.

Western Australia is another particularly anti-correlated region, according to Aecom 2016 modeling for the Australian Renewable Energy Agency (ARENA), “Co-location Investigation: A study into the potential for co-locating wind and solar farm in Australia â€. Take the 89 MW Walkaway Wind Farm (also known as the Alinta Wind Farm) outside the town of Geraldton on the west coast of Western Australia (see graphic at top right).

According to Aecom’s energy director for Australia and New Zealand, Craig Bearsley, one of the authors of the report, the great benefit of co-location is to “remove variability without adding cost.”

“It’s a fortuitous benefit of co-location that is free,†Bearsley continued, “and the benefit is greatest where you have greater anti-correlation… and with these hydrogen projects aiming for savings. of scale, obtaining benefits at no cost is a huge factor. . “

Battery storage

Another option being considered by large-scale green hydrogen developers, and not mutually exclusive with colocation, is battery storage. London-based Eco Energy World (EEW) recently announced a 300 MW solar power plant north of Gladstone in the Australian state of Queensland with a 200 MW hydrogen power plant and 100 MW of battery storage. However, as Orchard noted, battery storage is not yet a cost-effective option, hence why EEW CEO Svante Kumlin told PV magazine that the Queensland project would therefore require not only a grid connection, but also possibly a Wind Power Purchase Agreement (PPA). to run the plant at night and charge the battery. Of course, connecting to the grid remains an expensive and time-consuming process, especially in grid-constrained regions like Queensland, as Kumlin can attest. Therefore, these projects are at a disadvantage compared to projects like the 26 GW Asian Renewable Energy Center, which finds its economic basis in the advantages of co-location.

Oversized options

Whether it’s colocation or battery storage, the crux of the idea is to flatten the daily cycle, generating a constant pattern all year round, allowing the electrolyzer to deliver a base charge that can be liquefied, put in a pipeline, converted or otherwise transported. . And of course, as Wijk points out, oversizing means that the capacity of the electrolyzer needed for, say, 1 GW of solar power, is not 1 GW, but 200 to 300 MW, because the production is distributed over the daily cycle.

At much less cost, colocation also allows the flattening of the daily cycle, while saving on the capacity of the electrolyzer. It is not an average difference. After all, Wijk reminds us that “the cost of electricity is the dominant factor in determining the price of hydrogen… It is not the capex or the opex (although these costs have to be lowered)… When we have 1c / kWh, the energy cost of hydrogen is 0.5 € / kilo. And so when you have 2c / kWh the price is 1 € / per kilo, and 4c / kWh means 2 € / per kilo, and then the Capex and Opex costs add about 0.5 € extra … so you can see that you have to go to where you have the lowest energy costs thanks to renewables. And that’s in the areas where you have very good solar or very good wind, â€or what’s even better, very good wind and very good solar working together.

Location, location

Unfortunately, these requirements shatter the idea that large-scale green hydrogen can be developed around steel plants in rural areas, for example, in Germany, at least in the near future.

Of course, many countries will produce as much green hydrogen for themselves as possible, but the energy demand of countries like Germany or Japan far exceeds their natural wind and solar resources. Germany and Japan will need to import, and they will import from the cheapest possible sources, places like Algeria, Saudi Arabia and Australia, where large areas of desert and sea winds are normally available.

“For the production of green hydrogen, you always look for these sites,†emphasizes Wijk. The possible future scale required for green hydrogen is much larger than the current scale we have for electricity. After all, about 500 square kilometers are needed for 25 GW of solar power.

“So there will be competition,†Wijk continues. “And the competition is not necessarily what is the best technology or what is the most efficient, but what the cost of the system is the lowest. This is what must be seen, that a solar panel in Morocco has two to three times the output of the same solar panel in a northern latitude.

Pierre Etienne Franc, is the CEO of FiveT Hydrogen. The company has a hydrogen fund dedicated to the development of private large-scale clean hydrogen infrastructure. Frank notes, “Hydrogen is the common denominator between the industrial, energy and transport sectors, and ultimately offers the possibility for electricity producers to monetize their green electrons over a much wider range of local and export markets than if they were in the form of electricity. “

In other words, the demand for green hydrogen is not just about replacing the growing demand for electricity, but demand at all levels, and for this to happen, green hydrogen must be produced on a large scale. Given the enormous scale required for the production of green hydrogen to replace the demand for electricity, not to mention the larger industrial sectors detailed by Franc, it is in regions particularly suited to anti-correlated colocation that this scale is likely to be reached first.

[ad_2]